Rubber & Thermoplastic Hose Materials

There is an AIHP hose for every industrial and commercial application, and our constructions cover the full range of rubber and thermoplastic materials. Armstrong hose and tubings are made to accommodate the flow of: (as well as a multitude of corrosive and non-corrosive gases under vacuum or discharge pressure.)

- air

- water

- steam

- pharmaceuticals

- most chemicals

- acids

- alcohols

- oils

- greases

- gasoline

- alkalines

- solvents

- other corrosive and non-toxic liquids

(as well as a multitude of corrosive and non-corrosive gases under vacuum or discharge pressure.)

Chemical Resistance of Thermoplastic Hose

The tubes and covers of our thermoplastic hose are resistant to a wide number of chemicals, solvents and gases. The degree of their resistance is dependent upon, and will vary with, the concentration and temperature range of the chemical or solvent in contact with the hose. Thermoplastic and Rubber Polymer-Elastomers are available today to accommodate most chemicals and solvents in liquid or gaseous form. The life-expectancy of a hose tube or jacket, however, is directly related to the chemical effect of the conducted solvents, and also to the working conditions under which the hose is expected to operate, including atmospheric consideration and possible abrasion attack on tube and cover.

Almost all suppliers of thermoplastic and rubber hose make available charts and tables showing the chemical resistance of their materials. Many pages would be required to list all the liquids, gases and materials which thermoplastic polymers can accommodate. In lieu of such a list, (which would soon be made obsolete due to material improvements), we offer the following as a general guide to the chemical resistance of Armstrong hose:

Resistant to most chemicals wet or dry – including strong and oxidizing chemicals, organic acids, solvents, thinners, esters, ketones, aldehydes, alcohols, aromatic and many other hydrocarbons, freon and other gases, animal and vegetable fats and oils, grease, hydraulic fluids, alkaline solutions . . . plus resistance to ozone and other atmospheric conditions.

For more specific information, contact us for recommendations best suited to your hose needs.

Hose For All Specifications

AIHP hose meets or exceeds U. S. Food and Drug Administration, medical, NSF, and ASTM requirements, specific Military Specifications, SAE, and numerous specialized industry specifications.

AIHP’S Technical Department

Our Technical Department is ready to assist you with all your hose and tube design problems and needs. It is also available to aid in the development and production of a wide range of thermoplastic flexible shaft housings.

Water Hose – RV Connector Hose – Marina Hose

The Benefits to You:

- Name Recognition

- High Quality, Useful Product

- Repeat Business

- Loyal, Appreciative Customers

Armabraid Premier Hose:

- Superior Construction

- Durable – >15 yrs, 365/ yr.

- High Quality, Brass Fittings

- Constructed for Ease of Storage

Armstrong Thermoplastic Pressure Hose vs Conventional Rubber Polymer Hose Construction

Weight

Thermoplastic Polymers as used in hose constructions generally have a lower specific gravity than Rubber Polymers (which consist offiller ingredients and therefore add weight to the finished tube or cover). Example: A Hydraulic Hose with Thermoplastic tube and cover, and reinforced with double braid Nylon (DuPont ™), carries an identical working pressure and burst pressure rating as a Rubber Polymer hose with single-wire construction (SAE Specification 100R1 or SAE 100R5)-and the Thermoplastic hose weighs two-thirds less! In a comparison of air, chemical, or water hose for the same pressure specifications, Thermoplastic hose will be from one-half to two-thirds the weight of rubber hose.

Strength-Wearability-Abrasion Resistance

The wide variety of Thermoplastic polymers available for hose use permits selection from an exceptionally broad range of durometer hardnesses. The proper selection of Thermoplastic tube, cover, and reinforcement will provide for most applications a hose of toughness with strength and abrasion resistance unequaled by most rubber and “specially formulated” synthetic rubber polymer hoses.

Chemical Stability

The wide range of available Thermoplastic compounds, and the multitude of chemicals, solvents, liquids and gases to which each is resistant, permits hose constructions with a greater resistance to chemical attack than have ever been possible with hose of rubber polymer materials.

Flexibility

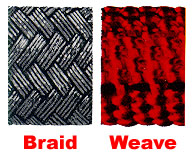

Because of the inherent strength characteristics of AIHP Thermoplastic polymers and the type of materials used for reinforcement, our hose is designed with fewer braids or weaves than ordinary Thermoplastic hose or rubber polymer hose. Instead of providing a hose with conventional double braid low tensile strength reinforcement, most Armstrong hose is designed with a single braid or weave of high tensile fibres. This light but strong reinforcement, coupled with extruded lower specific gravity Thermoplastic tube and cover Polymers, results in hose with smaller outside diameters and less weight. High tensile yarn reinforcements, such as Rayon, Kevlar or Nylon, offer greater resistance to fatigue from flexing and high surging impulse than most ply and braid reinforcements. High tensile yarn extends hose life.

Low-Temperature Flexibility

Thermoplastic polymers and copolymers in specific AIHP hose constructions are designed to maintain hose flexibility at minus degree temperatures.

Non-Toxic

Our hose tubes and covers are available for handling beverages and other edible liquids. The chemical ingredients of the tube compounds and, where necessary, the cover compounds, are manufactured with the most stringent Federal Food and Drug requirements.

Specialties

In addition to Thermoplastic Polymer hose of standard and special constructions, we manufacture many specialties that combine or make use of thermoplastics, rubber, weaving, and braiding. A few of these specialties are:

- Flexible Speedometer Castings – for the automotive O.E.M.

- Static Sound Depressor Casings-for industrial and automotive O.E.M.

- Flexible Shaft Housings- Thermoplastic flexible shaft housings, self-lubricating Extruded Thermoplastic Strippings and Forms . . . Non-Metallic Flexible Conduit-(asphaltum or lacquer finish loom sleeving or fibrous tubing).

Types And Availability

AIHP Thermoplastic and Rubber Polymer hose is available in a wide range of standard materials and constructions. Sizes of Thermoplastic hose range from 1/32″ ID up to and including 1 1/2″ID Most constructions are made entirely of electrically non-conductive materials. Special constructions can be designed and manufactured for specific original equipment machinery.

| Lengths | Thermoplastic hose constructions can be supplied in continuous lengths. |

| Color Coding | Hose can be made in any color on a production run. Individual hose colors permit coding for easy identification of materials being handled, assuring greater safety and reducing processing errors. |

| Couplings | A wide range of couplings is available for specific purposes. For most constructions, standard rubber hose couplings and fittings are recommended. |

| Shipping | Hose can be shipped in coils, in cartons, or to individual packaging requirements. |

There is an AIHP hose for every industrial and commercial application, and our constructions cover the full range of rubber and thermoplastic materials.

|

PRESSURE RANGE

Armstrong hose is available with constructions for simple gravity flow to pressures up to approximately 20,000 lbs. Burst.

TEMPERATURE RANGE

Armstrong Thermoplastic and Rubber Polymer hoses are available for applications requiring compatibility with temperatures ranging from -100°F to +500°F .